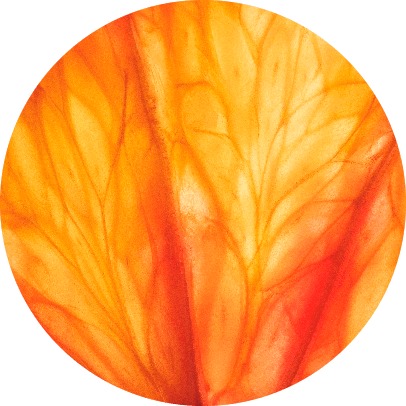

Il reparto dedicato all’estrazione erboristica è considerato il cuore dell’azienda. Qui avviene l’estrazione dei principi attivi dalle spezie ed erbe aromatiche.

Le spezie, macinate ad una pezzatura standard, sono trasferite nell’estrattore insieme al solvente, dove rimangono a macerare per un tempo predeterminato, quindi separate mediante torchiatura, centrifugazione o distillazione.

La G. Mariani & C. ha allestito un reparto di produzione di estratti e infusi con l’applicazione della tecnologia ad ultrasuoni:

una tecnica innovativa che unisce un ottimale recupero dei principi aromatici delle spezie all’ottimizzazione dei tempi di lavorazione.

La G. Mariani & C. ha studiato, realizzato e standardizzato un processo di estrazione dalle foglie di tè raffinato e articolato per le proprietà e la natura della matrice vegetale di partenza.

Alla fase iniziale di estrazione con acqua segue l’aggiunta di alcool etilico e un trattamento selettivo, grazie al quale l’estratto tè “grezzo” si libera dalle sostanze che possono compromettere la stabilità e l’aspetto finale. L’estratto tè finito, così ottenuto, garantisce la realizzazione di bevande perfettamente limpide e stabili nel tempo, dove l’esaltazione delle note aromatiche delle foglie di tè sono abbinate ad un piacevole e caratteristico colore ambrato.

Con una materia prima naturale, quale è il succo di frutta concentrato, realizziamo semilavorati aromatici adatti alle diverse esigenze dell’industria alimentare.

Omogeneizzatori, pastorizzatori ed emulsionatori sono le attrezzature e le tecnologie disponibili in questo reparto.

Le sperimentazioni in laboratorio e la produzione sono intimamente legate e consentono la realizzazione di prodotti sia tradizionali che nuovi. Attraverso l’utilizzo di apparecchiature specifiche si ottengono diverse tipologie di aromi, emulsioni e aromi sia liquidi che spray dried.

Una sperimentazione lunga e rigorosa permette di ottenere emulsioni efficaci e stabili nel tempo. Questi prodotti sono utilizzati nelle bevande per conferire torbidità, aroma e colore.

All’interno dei laboratori modernamente attrezzati, materie prime, semilavorati e prodotti finiti vengono controllati - sia attraverso metodi d’analisi tradizionali, sia con tecniche studiate e messe a punto per le esigenze specifiche della nostra realtà.

Accanto alle attività proprie del Controllo Qualità i laboratori presenti nella nostra azienda sono impegnati in attività di Ricerca e Sviluppo dove il dinamico lavoro di cooperazione tra tecnici aromatieri ed esperti di marketing è in grado di anticipare le tendenze di mercato e di realizzarle al meglio nell’interesse della clientela.

Grande è l’impegno rivolto alla predisposizione delle Campionature, con più di 5000 campioni trasmessi ai Clienti ogni anno. La validazione del campione spesso è accompagnata dalla sua valutazione nell’alimento finito, così da fornire al Cliente l’aroma che meglio risponde alle sue esigenze, corredandolo anche di tutte le informazioni necessarie al miglior utilizzo.

La G. Mariani & C. dedica particolare attenzione allo stoccaggio e alla conservazione delle materie prime, dei prodotti finiti e degli imballaggi.

La disponibilità di 3000 Mq di magazzini, di celle refrigerate a diverse temperature, una razionale diversificazione degli spazi, un’identificazione univoca dei prodotti stoccati unitamente ad una gestione FIFO, permettono di disporre - in qualsiasi momento - di un prodotto correttamente conservato e facilmente rintracciabile.

La realizzazione di liquori, come quelli a base di crema latte e i concentrati liquerizia, permette alla G. Mariani & C. di offrire una elevata versatilità dei reparti produttivi.

Aromatizzate nei gusti tradizionali, in gusti innovativi o fornite come matrice alla quale il cliente dà la personalizzazione finale, le “creme” hanno la caratteristica di stabilità nel tempo, nonostante la composizione sia estremamente delicata.